Serpentine Systems

This page outlines what I’m I’m trying to accomplish with the serpentine systems.

PRE-DYNO

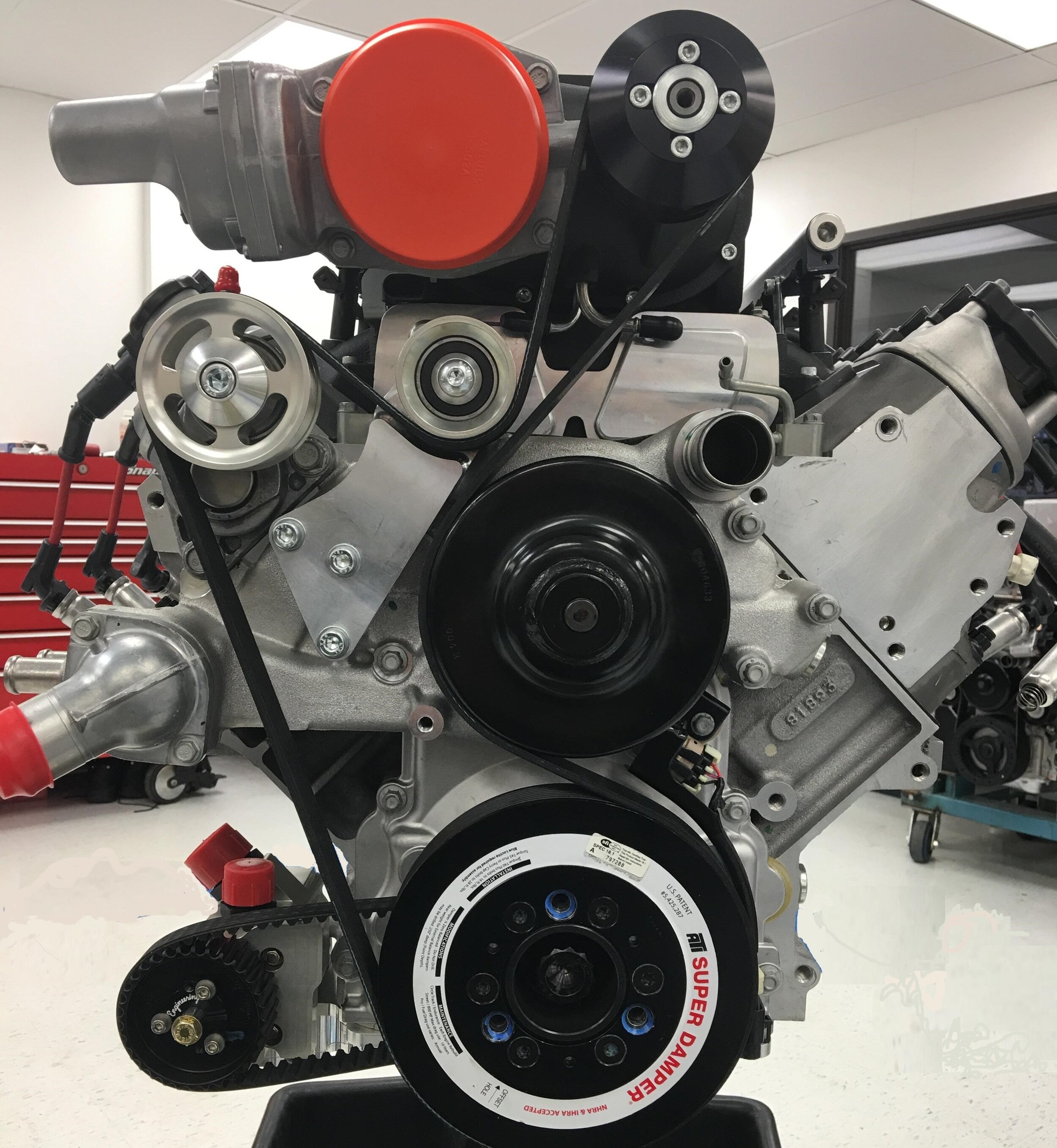

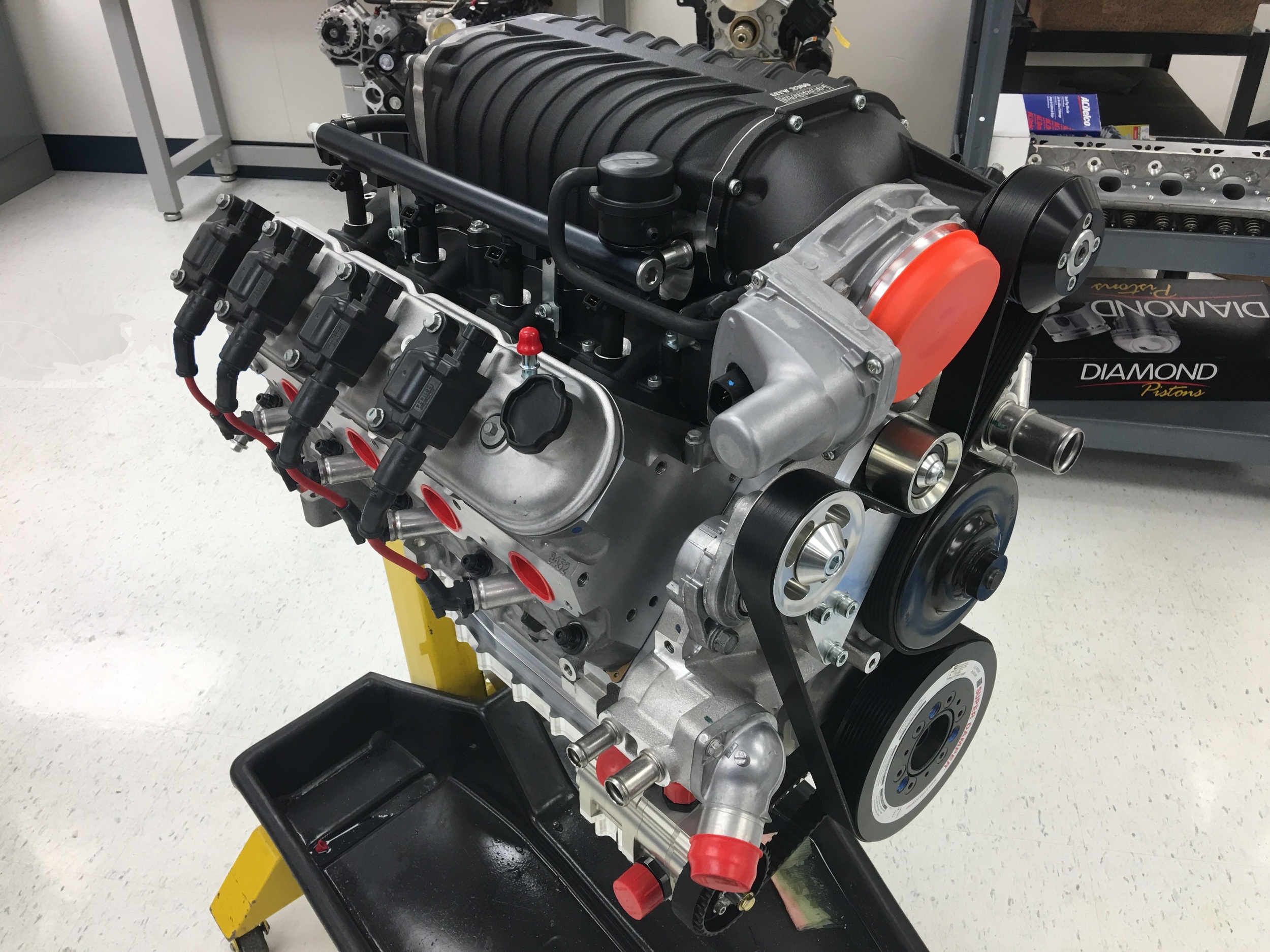

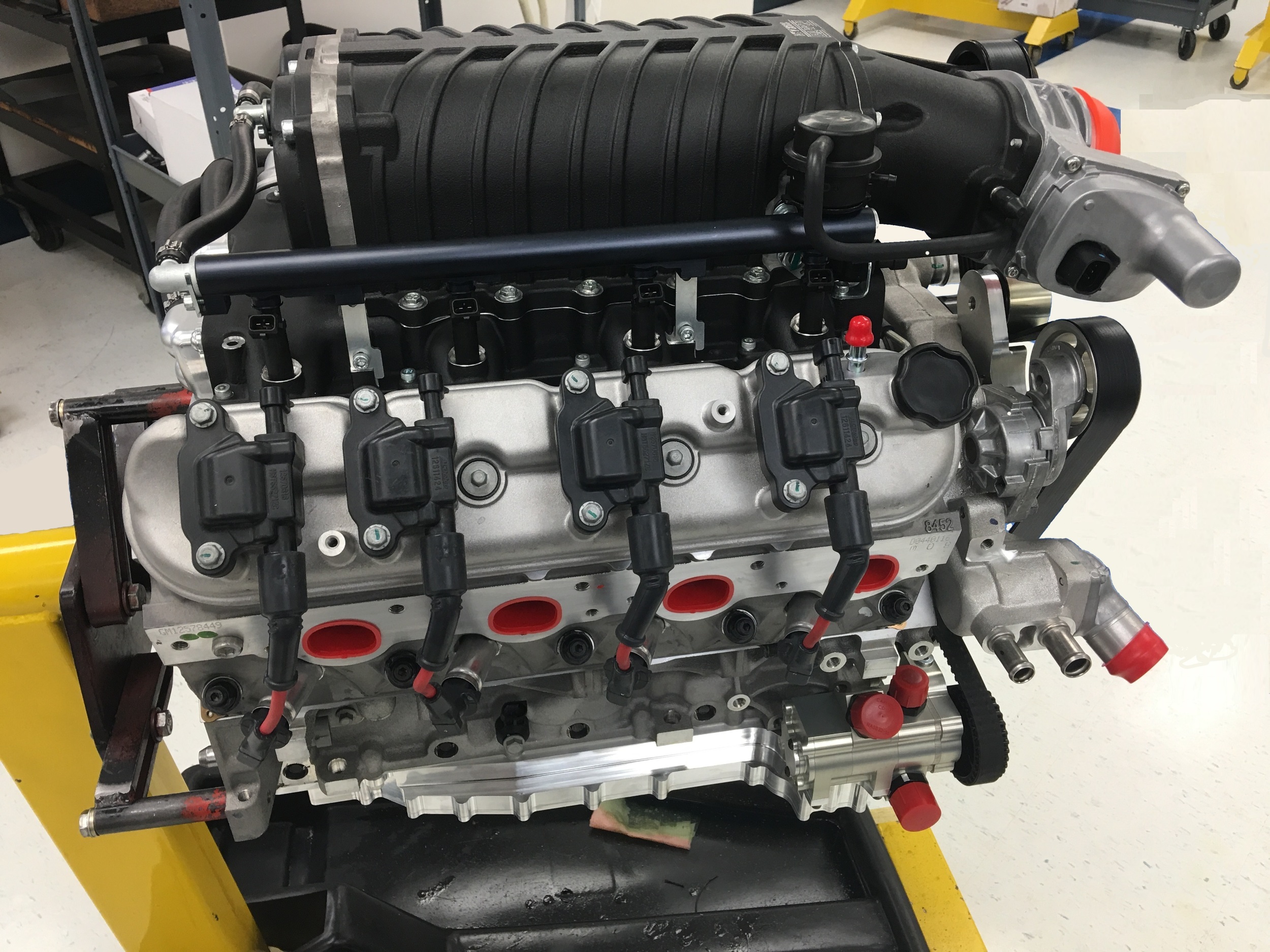

This was the engine just before it went on the dyno…

The belt is a Gates K080653; 8 ribs, width 1.087", effective length 65.36”

ATI Super Damper:

Hub # 916033A. It drives the Daily dry sump via a cogged belt

Shell assembly # 917025 with 7.36” diameter. ATI has their super dampers on this page.

The Harrop supercharger pulley doesn’t have a art number on it and I took the following measurements (i.e., not particularly accurate); Rim OD: 3.35”, Rib OD: 3.17”, Depth: 1.9”

Automatic tensioner: AC Delco12569301

Current Situation

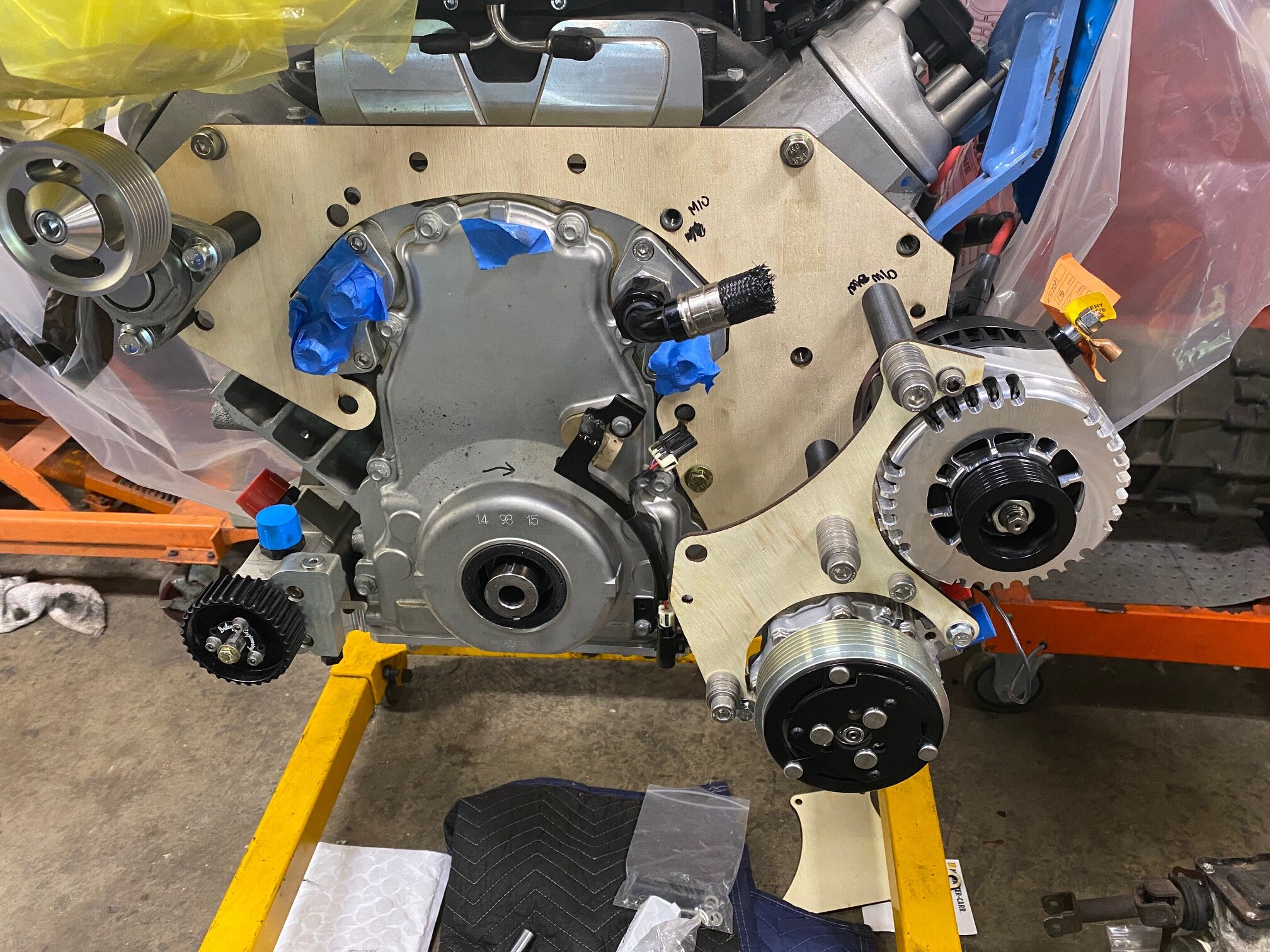

The mechanical water pump has been replaced by a remote electric one.

The ATI shell assembly was upgraded t to 10 rib 6% over drive with an 8” in diameter (note the one in the picture above is 8-ribs)

I had a custom accessory pully machined. It mounts to the super damper, has 6 ribs and the OD is 6.46” It has a standard Chevy big block 3.2" bolt circle and recess with a 2.050" ID.

The above pulley will drive the A/C compressor and the alternator.

ZPE will machine a custom 10-rib supercharger pulley with GripTec Micro: a patented micro ablation machining process that creates multi directional ridges and valleys that increase maximum gripping force and act as escape ducts for trapped air and debris further helping in the mating of the target surface and belt.

I mocked custom plates in plywood (see pictures above), these are designed in Solidworks 2016.

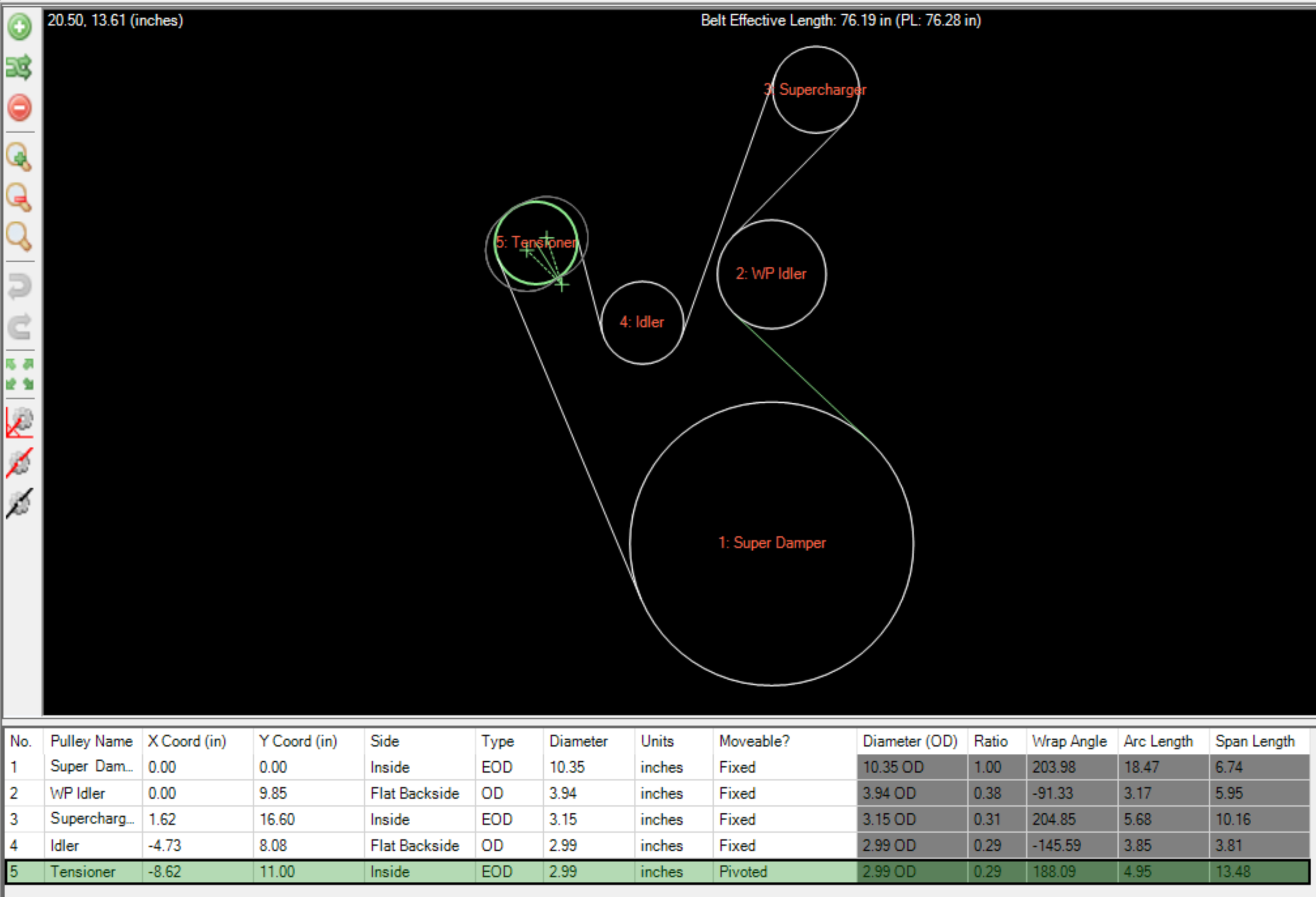

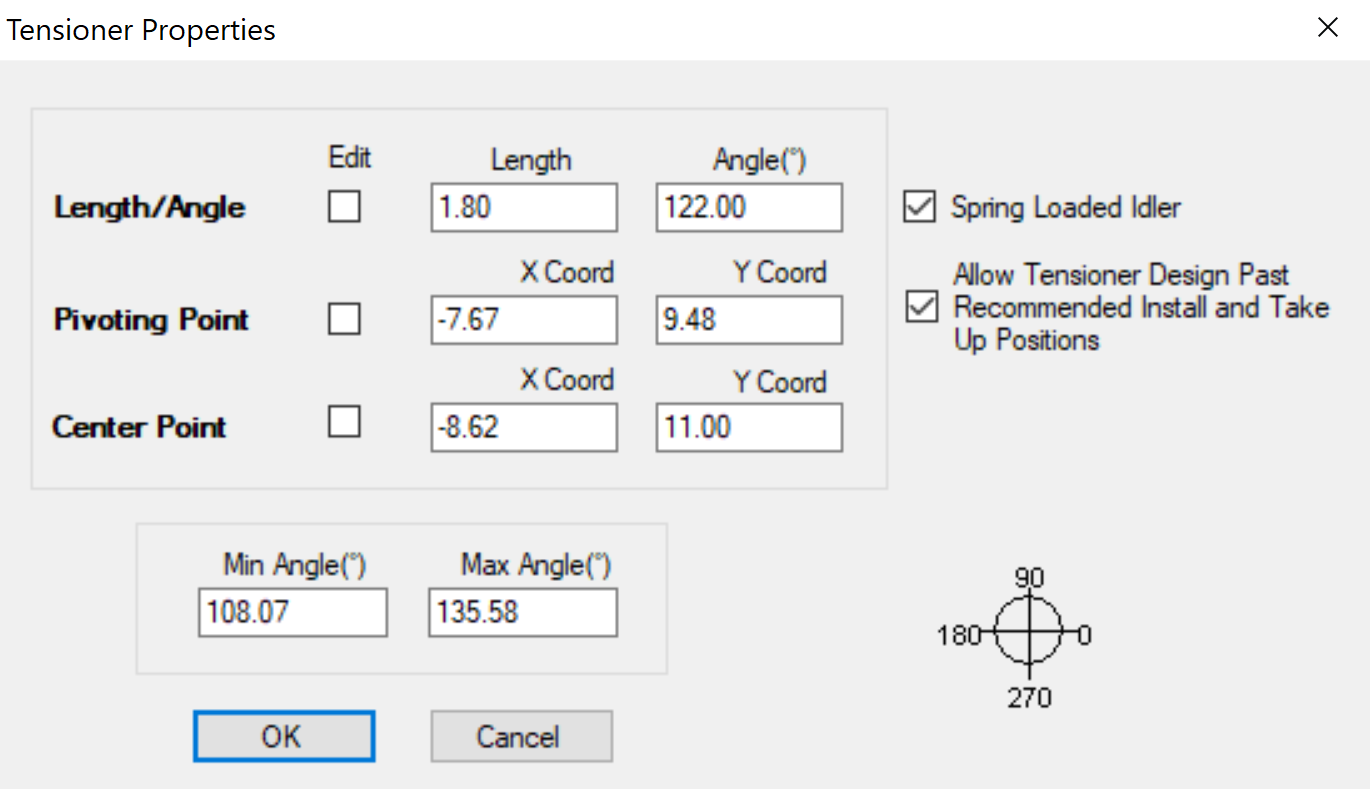

I entered the pulley layouts in Design IQ, free software from Gates available here.

Next Steps

I need to spin it at 21,000 RPMs. To accomplish this I need to change the shell assembly to supercharger ratio. To prevent the supercharger pulley from slipping, the best way to accomplish this is by increasing the size of the shell assembly rather than shrinking the supercharger. ATI can machine a custom 10.35” shell assembly (takes a min of 120 days!). I should be able to fit this because I don’t have a water pump.