I'd be a excellent human-powered battery

I have an amazing ability to steam up a car. I'm not sure what the hell the issue is, but it starts at the window nearest me and migrates out in a radial pattern. I'm sure that I would make a great human battery for the Matrix -- LOL

In any event, the SL-C can run hot and while I don't need as much HP as I have, I do need a really good A/C system. When I went to install the supplied Vintage Air Slimline evaporator I discovered that it wasn't even close to fitting because I had purchased the optional removable side-impact bars. The only way to make it work is to rotate it 90 degrees and cut a big hole in the monocoque. I resisted doing this for a long time, but I'm now convinced that it's the only viable option.

So, I started down that path and I laid out the Slimline unit and all of the electronics. It was at this point that I realized that the fan unit only had three speed settings; low, medium and high. To fix that limitation I was planning on using a MoTeC PDU to Pulse Width Modulate (PWM) the fan to get infinite fan speeds. There must be a better way, right? After a lot of searching I found RestoMod Air who makes a high-end solution. While none of the other builders have used one, it appears to have the following advantages:

- Smaller cut in the monocoque

- Serviceable box (not all glued together)

- Electronic controls; mode, temp, dash/defrost/heat

- Bluetooth control via iOS or Android app

- Better quality – at least according to their over-the-top marketing

- Really nice billet control options, including a single-button one

- SPAL fan with infinite speed control

- Separate heating and cooling coils

The primary downsides are:

- It's 4.25" taller and might take too much space in the passenger's foot box

- The heater control valve doesn't have a bypass (i.e., won't work with a LS engine)

- No one has installed one in an SL-C yet

- The vents point upward so I'll have to design custom 3D-printed adapters

- It's comparatively expensive

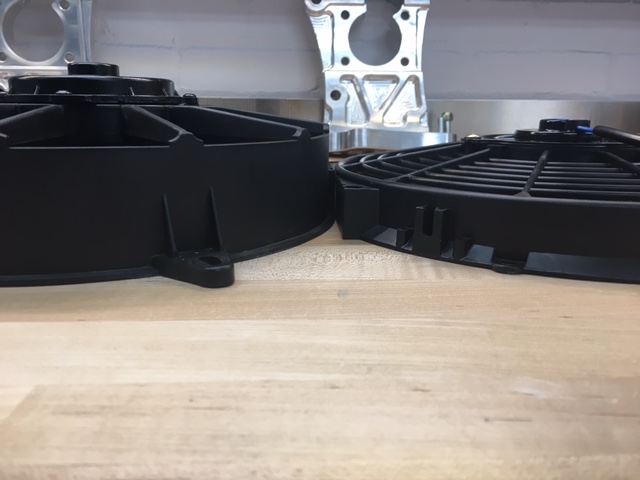

The first two, are the only real issues. I called RestoMod and they offer a mocking case which includes a plastic motor house for $125. It's refundable so long as you pay shipping both ways. I ordered their two smallest Bluetooth-enabled versions; a Bantam II and a Vapir III. The picture below shows the actual size (hole will need to be a little larger) of the two units and their approximate location. The longitudinal orientation is due to the removable side impact bars which prevent it from being installed transversely. The rectangle with the black border represents the increased length of the Vapir III.

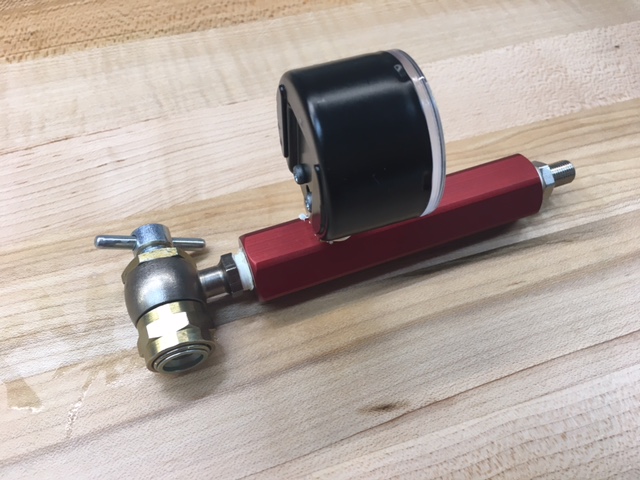

The heater control valve actuator is from the same Chinese supplier as the one that I made a 3D bracket in this earlier blog post, but the output shafts are different, the mounting holes are different and the ECU is integrated rather than being standalone. So, I either need to machine a shaft adapter and print a new 3D bracket OR maybe I'm lucky and the control protocol is exactly the same and my current actuator will just plug-and-play. The wiring connector is the same. Anyone want to bet which it will be?