“Yeah sweetie, this is how a man accessorizes... a dress needs shoes and Penske shocks need a nitrogen setup LOL”

I went to reinstall the shocks the other day and I couldn't compress them at all, let alone the couple of inches required to fit them between the mounting points. This is because they are filled with about 150 psi of nitrogen (apparently the national championship SL-C ran 175 psi). There are three approaches to reinstalling the shocks:

- Bleed the nitrogen. This makes it easy for a single person to do it. The downside is that you need to refill them with nitrogen.

- Compress the shock in place. This requires careful use of a crowbar and two people. You might want to tape the top of the shock absorber to prevent it from being scratched by the crowbar.

- Compress the shock on the bench. This requires you to compress it to the correct length and use wire to keep it compressed while you position it in place at which point you cut the wire.

I really didn't want to struggle getting it in place given that once it's in place you need to slide the bolt through a safety washer and two grade 8 washers on each side. So option one seemed best. The only downside with that approach means that you need to refill it with nitrogen which means that you need to buy more tools. The upside is that you get to buy more tools and you're set up to tune the pressure when you go to shake out the car.

The following are required to change the amount of nitrogen in the shocks:

- Shock inflator

- High-pressure regular

- High-pressure hose

- Nitrogen bottle

The shock's oil reservoirs have a standard Schrader valve like you'd find on a car tire. However, you don't want to use standard tire inflation tools for two reasons: (1) the pressure is 150-200 psi which is 4-6 times higher and (2) there is a very small volume of nitrogen which means that the pressure is extremely sensitive to leakage when connecting or disconnecting to the valve. In fact, even specially designed shock inflators will reduce the pressure by 15-20 psi when checking the pressure. Note that the gauge will read the lowered pressure, not the pressure before you connected.

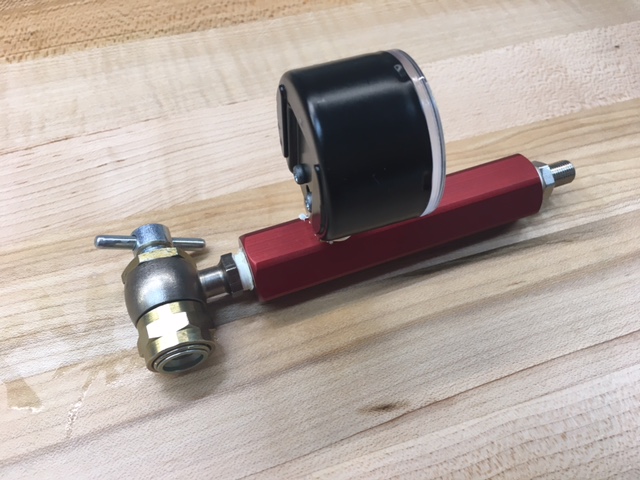

A shock inflator has a special high-pressure, no-loss chuck. It's used as follows:

- Rotate the T-handle counterclockwise until it stops. This retracts the plunger.

- Attach the chuck to Schrader valve. It uses a copper seal ring so it needs to be tightened a little with a wrench or it will leak. Be very careful not to damage or twist the Schrader valve. Ideally you would use a second wrench to hold the Schrader valve, but I couldn't get even my thin Snap-on box wrench to fit.

- Slowly rotate the T-Handle clockwise to extend the plunger. If you hear any leaking, rotate the opposite way and repeat the above step. Keep rotating until the gauge shows the pressure.

At this point you can bleed the nitrogen from the Schrader valve on the inflator. Remember there is a very small volume of nitrogen so it's a thousand times more sensitive than bleeding pressure out of a tire. If you bleed all of the nitrogen out you'll want to re-inflate to at least 50 psi to keep pressure on the seals (I'll write that up later). When you've reached the desired pressure via inflation and/or deflation:

- Rotate the T-handle counter clockwise until it stops. This retracts the plunger.

- Loosen the chuck from the Schrader valve. The nitrogen that you hear is vacating the body of the inflator. Nothing leaks from the shock.