While mounting the Y-block for the intercooler inlets, I couldn’t get the screws to lay flat. WTF? There isn’t enough of a flat spot to accommodate even a #10 socket head cap screw because they apparently used a ball end mill to machine that surface. All they needed to do was flatten it with a square end mill. I’m not talking about a separate operation, but rather a simple tool change. The piece is beautifully machined, but for $116.29 I expect better. In any event, it was simple enough to fix it with a center-cutting square end mill.

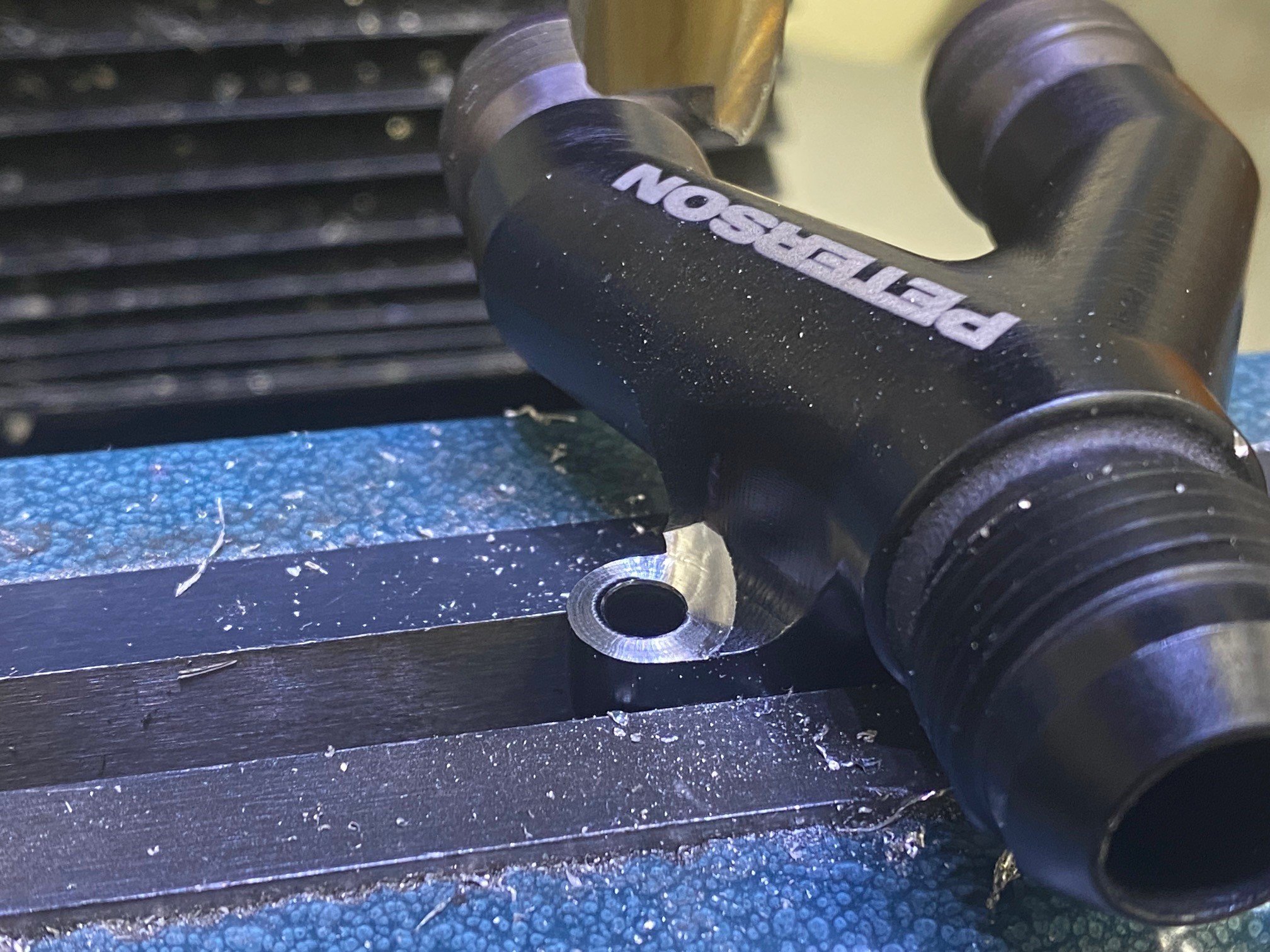

Note the radius created by the ball end mill; the taper in the “Y” results in the rear radius being worst than the front

Flat spot created with a square end mill; note the depth of the cut in the rear

The next step was to fabricate a bracket to mount the Y-block to the rear of the left cylinder head. Unfortunately, the Y-block was located over one of the cylinder head’s M10 tapped holes. To solve that, I used flathead screws and a 1/4” thick piece of aluminum to accommodate the depth required to countersink the screws. I designed the bracket to extend past the cylinder head and I used Reflect-A-GOLD tape on the backside to provide a heatshield from the exhaust. The bracket was laser cut, the edges cleaned up with a belt sander, the corners broken with a deburring wheel and the surface brushed with a finishing wheel. The two tapped mounting holes for the 10-24 screws were drilled on a mill because they were too small to be reliably laser cut (the rule of thumb is that holes and interior geometry must be as least 50% the thickness of the material being cut).

Bracket ready to be mounted. Note the depth of the M10 countersunk hole in the lower right

Y-block mounted to the rear of the left cylinder head

Bracket is covered with Reflect-A-GOLD to provide heat shield from the #7 exhaust primary