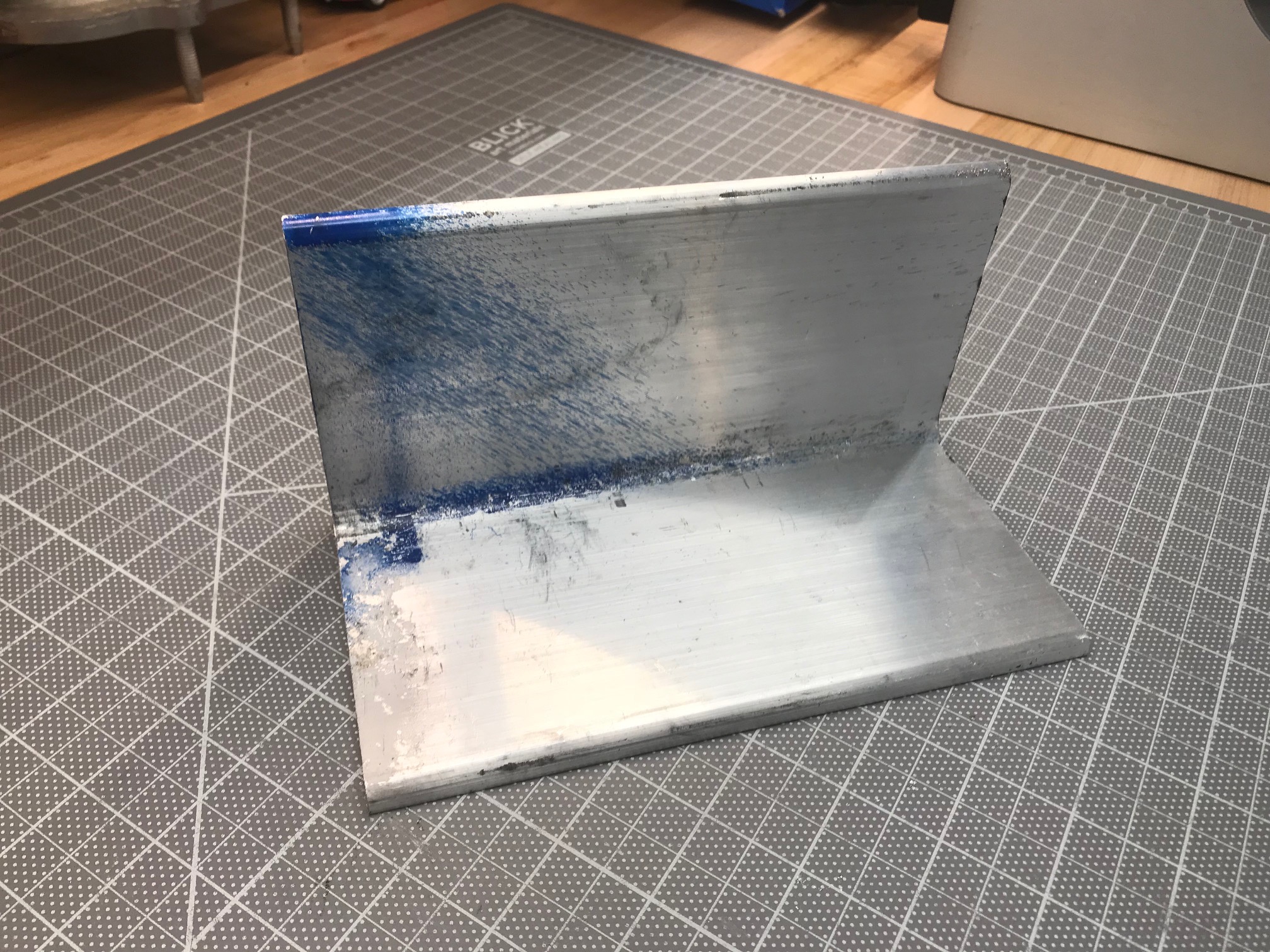

I mounted the hydraulic lift pump today. There wasn't an easy way to mount it where I wanted it so I fabricated a bracket. The only right angle aluminum that I had that was tall enough was 1/4" x 4" x 4", which was overkill. After cutting it down to size, drilling the mounting holes and cleaning the edges up on the sander, I milled two openings to reduce weight.

The bracket that comes with (and is required to mount to my bracket) was damaged in shipping so I removed it to straighten it. I noticed that there was some oil between the pump body and the bracket. Apparently, the two mounting bolt thread directly into the pressurized part of the pump. As can be seen in the picture below, they stack two small o-rings on the bolt to prevent the oil from leaking. There are no groves and the pump body has a 2.5" diameter (i.e., it's no flat) which results in a less than ideal seal. I considered using some 1/32" rubber to make a gasket, but that would reduce the amount of thread into the body and the o-rings wouldn't get as compressed. I also thought about 3D printing a curved washer, but I was concerned that it would be so thin that it might eventually crack. So I decided to use a little Room-Temperature-Vulcanizing (RTV) silicon.

After installing it, I realized that I could have tapped two holes into the 2" x 2"for the bottom two bolts and used a much smaller piece of aluminum for the top two bolts... oh well.

To complete the hydraulic lift pump I need to install and plumb the reservoir and plumb the lift rams. To do that I need to order some more hose ends and wait for Penske to return my reconfigured shocks.