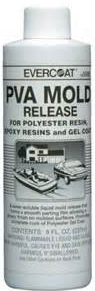

Mr. Miyagi would have been proud, FIVE coats of mold release wax!

I decided to make a mold and practice part rather than cutting the body any further to experiment with the tail light. If I make a mistake, I can just make another part -- much less crying that way. In addition, this will enable me to sculpt the contour around the tail light on my bench (rather than on the car) and take a mold of that when it's ready... well, that's the theory.

My biggest concern in doing this is that the mold gets stuck to the bodyand wrecks it. This is what I did to make the mold:

- Devised way to support tail in vertical position; it's easier to fiberglass with gravity pointing in a helpful direction

- Protected the area around the mold with painter's tape and plastic

- Applied five coats of mold release wax; wax on wax off

- Sprayed 10 coats of Polyvinyl Alcohol Release Agent (PVA)

- Applied tooling gelcoat; I couldn't get the !$%@ gelcoat gun to work so I just did it with a brush

- Applied 10mil fiberglass surfacing veil and resin; this prevents subsequent layers from showing through the gelcoat

- Applied medium-weight cut strand mat and resin

- Applied 10oz fiberglass cloth and resin; add bi-directional stability

- Applied 2mm high-density bulker mat and resin

- Applied 13.5oz chopped strand mat and resin

- Fiberglassed mold stiffeners; I used some 1" PVC tube

PVA is cool stuff. It's basically plastic dissolved in alcohol which when sprayed provides a thin plastic layer which keeps the gelcoat/resin from sticking. It's fairly translucent and I was worried that I wasn't getting enough on the surface. So I applied too much and I got a lot of drips and runs. So first try was peeled off. The following day, I applied another ten coats and I went to get a cup of coffee while the final coat was drying. When I went back to check, the PVA layer had a lot of holes in it... PVA is water soluble and apparently there was a rogue drizzle that wrecked it (not noticeable on driveway but there were a couple of visible drops on the garbage can lids). I was on my eighth coat of the third try when the guys redoing my slate roof turned on a leaf blower to clean the 90+ years of dust off before putting down ice and water shield -- really? So let's hope the fourth attempt works.

Did I need that many coats of PVA? Probably not, but I'm paranoid that the mold will get stuck and wreck the body.

I used isophthalic polyester resin because it's allegedly one the toughest resins out there and also offers lower shrinkage and a higher distortion temperature; important characteristics in mold construction. It uses a Methyl Ethyl Ketone Peroxide (MEKP) hardener which is really toxic stuff.

YES MOM, no need to ask again. I am wearing a mask, gloves, etc.

It took a bit of work to get the mold off the tail. Fortunately some YouTube videos let me know what to expect or I would have gotten really stressed out. The PVA worked really well. In the picture to the right, the thin film is the PVA being pulled from the mold. I'm happy with how it came out, but I now realize that I probably made it twice as thick/strong as it needed to be.

I also received my Ricardo transaxle today! They have become extremely difficult to get and I'm very lucky to have a new one. Given my high-HP engine I had it taken apart, inspected, the gears "super polished" and then reassembled and tested on a dyno. I now need to figure out an oil cooler and thermostat.